Products: aviation

| Our actuation systems for the aviation

industry start from variable-pitch

propeller actuation for ultralight

aircraft over throttle actuators, landing

flaps drive systems and (elevator) trim

drive systems for business aircraft (turboprops

and jets) to primary flight controls.

We also develop actuation systems

for landing gears.

Our activities

cover all mechatronics topics:

mechanical engineering, eletrical

engineering and information technology. Working in many

projects in different actuation applications we gathered

a broad range of experiences, supported by in-house

development activities (especially with sensors and filters).

There we work in addition to the typical electro-mechanical

signals (which are in many actuation systems) especially

with transducers for flight-mechanical information (air

data, inertial data). |

|

|

| The demands in the aviation industry very

often require a customised approach, to

fulfil the safety requirements (under

restricted space conditions) over the

necessary temperature range or under

vibrations. Especially for technology

demonstrator programs we have a broad range of

solutions, from which we participated in

several national and international

programs.

|

|

|

| It is a vital part of our profile to carry out

the calculations of estimated operation

time (fatigue life of bearings, gears),

operation limits (buckling of the spindle

actuators) or thermal behaviour, which

are necessary for the certification. We

also plan and supervise the required

environmental tests (climate, vibration,

EMC). |

|

|

| The reliable operation of electro-mechanical actuation systems

depends also on the behaviour of the on-board power supply (mostly DC with battery backup).

The characteristics of these power supplies require protective measures to fulfil the

avionics requirements (e.g. RTCA DO-160, MIL-STD-1275). These requirements are true for both the

electrical and the mechanical topics. |

|

|

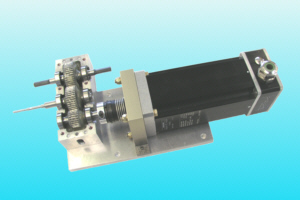

Example: LAPAZ -

actuator electronics for flight control (with

Stemme AG)

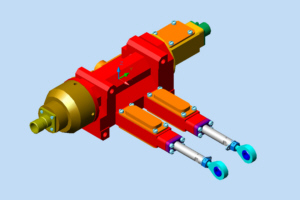

Example: landing flaps

drive system (spindle force 12 kN resp. 2700 lbf)

Example: landing flaps

drive system (spindle force 4 kN resp. 900 lbf)

Example: elevator trim drive system